Malaysia Online Tyres Store. Kedai Tayar Kereta Maya. Website works best with Google Chrome.

Tell Me About

I want to know

Talk like a Pro

Carcass

Carcass

Plus-Sizing

Plus-Sizing Rim Width

Rim Width

Plus sizing is one of the easiest way to achieve enhanced performance and improve the appearance. In this example, a 17x7 wheel with a 205/65R15 is considered the Original Equipment size.

Plus sizing is one of the easiest way to achieve enhanced performance and improve the appearance. In this example, a 17x7 wheel with a 205/65R15 is considered the Original Equipment size.

The load indicator refers to the load-carrying capacity of a tyre, or how much weight a tyre can support. For example, if a tyre has a load indicator of 89, it can support 1,279 pounds (from below chart) at maximum air pressure.

|

Load Indicator (Symbol and maximum load in Lbs & Kg)

|

|||||||||||

|

LI

|

Lbs

|

Kgs

|

LI

|

Lbs

|

Kgs

|

LI

|

Lbs

|

Kg

|

LI

|

Lbs

|

Kg

|

|

71

|

761

|

345

|

81

|

1,019

|

462

|

91

|

1,356

|

615

|

101

|

1,819

|

825

|

|

72

|

783

|

355

|

82

|

1,047

|

475

|

92

|

1,389

|

630

|

102

|

1,874

|

850

|

|

73

|

805

|

365

|

83

|

1,074

|

487

|

93

|

1,433

|

650

|

103

|

1,929

|

875

|

|

74

|

827

|

375

|

84

|

1,102

|

500

|

94

|

1,477

|

670

|

104

|

1,984

|

900

|

|

75

|

853

|

387

|

85

|

1,135

|

515

|

95

|

1,521

|

690

|

105

|

2,039

|

925

|

|

76

|

882

|

400

|

86

|

1,168

|

530

|

96

|

1,565

|

710

|

106

|

2,094

|

950

|

|

77

|

908

|

412

|

87

|

1,201

|

545

|

97

|

1,609

|

730

|

107

|

2,149

|

975

|

|

78

|

937

|

425

|

88

|

1,235

|

560

|

98

|

1,653

|

750

|

108

|

2,205

|

1,000

|

|

79

|

963

|

437

|

89

|

1,279

|

580

|

99

|

1,709

|

775

|

109

|

2,271

|

1,030

|

|

80

|

992

|

450

|

90

|

1,323

|

600

|

100

|

1,764

|

800

|

110

|

2,337

|

1,060

|

When cleaning your tyres, use a soft brush and be careful around the edges of your wheels. You can use special cleaners, but typically the mild detergent you are washing your car with works well when you use a brush. After washing your tyres, dry them and apply a tyre dressing. This will enhance the beauty of your entire car and will help prevent the exposed sidewall rubber from cracking or checking. Following these simple steps will enhance the beauty of your car and will help your tyres look great for years to come.

A wide range of tyre choices is available for every vehicle. Understanding the types of tyres will help you make the right choice. Tyre types can be grouped by their application: Cars and Minivans, 4x4 and SUV.

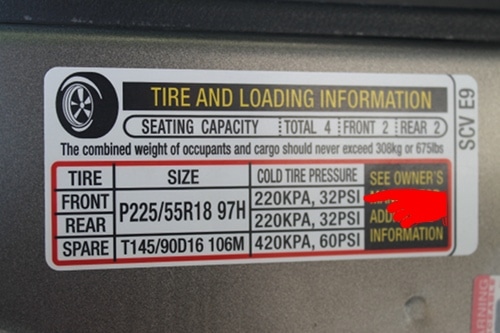

Where To Find Air Pressure Information

Where To Find Air Pressure Information In this example, add 3 psi in the right rear tyre to match the other rear tire's warm reading. When the tyre returns to cold pressure, it should end up at the recommended pressure.

In this example, add 3 psi in the right rear tyre to match the other rear tire's warm reading. When the tyre returns to cold pressure, it should end up at the recommended pressure.

Ride Height

Ride Height|

Misalignment Condition

|

Tire Wear Symptom

|

|

Incorrect Camber Setting

|

Premature smooth wear on either inside or outside shoulder

|

|

Incorrect Toe Setting

|

Feathered wear across tread, raised tread block edges

|

|

Incorrect Caster Setting

|

Excessive shoulder wear, tread blocks show "heel-toe" wear pattern

|

|

Unequal Caster setting (either right or left side is out of specification)

|

Sharp pulling necessitates steering compensation and feathered wear

|

|

Unequal Toe setting (either right or left side is out of specification)

|

Sharp pulling necessitates steering compensation and feathered wear

|

|

Combination of two or more settings are out of specification

|

Irregular tread wear with feathering and smooth spots

|

<- Static Imbalance:

<- Static Imbalance:Rotating your tyres periodically is an essential part of tyre maintenance. The main purpose of regularly rotating tires is to achieve more uniform wear for all tires on the vehicle. If no rotation period or pattern is to be found in your owner's documentation, rotate your tires at least every 10,000 km and follow one of the patterns suggested below.